Building Confidence

| Volume 10 Issue 5 ISSN 1923-7162 |

Welcome to Dave's Shop Talk's Home Improvement Newsletter of questions from our members on their construction projects, a Tip of the Month and a home remodeling article, both from our website at http://daveosborne.com.

Tip of the Month

When cutting identical pieces of boards for opposite ends of a project, place the pattern on the piece to be copied good face against good face. This way both opposite ends will have the best side of the pieces facing out. With the wood we get nowadays, each piece seems to have a good side and a bad side: Ref: Remodeling 12: How to Cut Crown Molding.

And a Bonus Tip:

When buying an older house, pay that inspector his dues. He'll give you a report of what needs attention and your offer on the house can be based on this report: Remodeling 21: Wood Framing Answers.

Ask Dave!

Hi,

I'm currently renovating my entire kitchen and first floor of my home. I'm taking the floor right down to the 1/2" plywood subfloor that sits on the 16" centers floor joists. There is quite a bit of water damage so I will be removing the subfloor down to the joists where necessary. My question is this:

Should I remove ALL the 1/2" subfloor, even the dry non-compromised areas and just start from scratch? OR Would it be OK to match the existing 1/2" with new 1/2" plywood then move up from there? I plan on putting down 23/32" plywood over the 1/2" and then 1/4" backer, then 1/4" Porcelain tile. Gluing and screwing in a 6x6 pattern. What do you think? What would you do?

Thanks,

Greg

Hi Greg,

Sounds like you have it under control. The code says you need 1 1/4" of solid sub-floor for ceramic or porcelain tile.

If it is easier to remove any small pieces of 1/2" and replace with a full sheet, I would do that, rather than put down small pieces. All joints should be across the joists. The layer on top of the 1/2" should be tongue and grooved, 5/8" utility sheeting. Stagger all joints, keeping the grain of the plywood going across the joists. Some underlay, the 1/4", calls for a 4x4 nailing pattern, usually 1 1/8" staples. Screws with glue is better!

Dave

Dave,

What is the correct way to frame ceiling joists and rafters? Do the joists have to be offset, or can they butt up and be tied together? I have seen instances where rafters were not offset, but a book I looked through shows them offset. I know trusses are more simple, but I want to stick build a roof.

Thanks Much,

Mike

Hi Mike,

Yes, most definitely the ceiling joist can be butted up to each other over a bearing wall. BUT, you need to apply a scab over the two joists at least 2' on each joist - 4' over all, nailed securely to keep the joist from pulling apart when a load is introduced to the roof. This scab is made of the same material as the joists. I nail at least 6 - 3 1/4" nails on each side of the splice. Depending on the roof span and snow/wind load, the number goes up to 11 nails until trusses are required over large spans and heavy loads. Just think how many nails you have at the ends of the joists - to rafters and to the plate, then use this same number plus 1. Make sure the nails are spread out, this depends on the length of scab, also.

Dave

Good morning, Dave!

How about plans for some window planters? Should be pretty easy, eh?

Yes, they shouldn't be too hard. I just would get some solid 1" rough material, like cedar and cut the ends on an angle, such as in the drawing, below:

If the sides are 2 or 3 boards, instead of a single one, just add vertical studs, on the inside to help tie the sides together. Dave

I need to build a wood porch across the front of this house and they want a gable roof. The width across the house is 28ft. (just under the eagle on the left and 32" in from the right side just before the window. I need to know how to build the gable as wide as they want it to be or if you have a better idea. I did see a house that had what looked like a gabled hip. Also, many thanks for the stair calculator, works great.

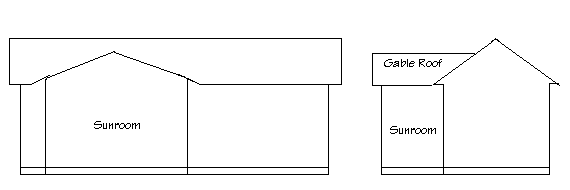

Here is a drawing to help explain. This drawing is not proportional to your situation:

Concentrate on building the foundation - posts and pads or walls and footings. Have the gutters match with the existing building. For a gable roof, run the ridge into the existing roof and frame down onto it. Remove the roofing material down to the sheeting. Place a 2x4 on the flat, nailed to the roof sheeting. Remove the roofing material down to the sheeting. Place a 2x4 on the flat, nailed to the roof sheeting. this will form the valleys. Nail your valley rafters to the ridge and to this flat 2x4.

The one thing to watch with all this is not to have the ridge going higher than the existing ridge. You can do this, but it looks better and less problems if the porch ridge comes into the house below the height of the house ridge. The height of the ridge depends on the span, so if the span of the porch roof is less than the span of the existing roof, you will have the ridge come lower. That is if the slopes are the same. Check that the 28' they want for the porch span is less than the span of the house. I hope this helps. If not, send me more specific info on the slope, spans, etc.

Glad the stair calculator helped.

Dave

We are planning to build a sunroom along the south side of the garage. The garage wall where this sunroom will be built is two stories tall. The proposed sunroom will be approximately 15'X15'. The plan is to use rafters from the existing wall that will be not more than 4/12 pitch.

Since we intend to install three large Velux roof windows in the roof, we would prefer to achieve a clear span for the entire length of the rafters. The question is can we use 2x8 for this length or will we need to use something larger, perhaps as much as 2X12? We are located in eastern Maine, so snow load is the consideration that we must be concerned with.

My intention is to frame without birdsmouth, using clips on top of the south wall to hold the rafters to insure full strength of the rafter material over the whole length.

Comments will be much appreciated.

Will you be installing roof joists or rafters and ceiling joists? If this is a lean-to type of roof, which I think it will be, normally you would use roof joists. These are similar to floor joist, but on a slope. On the garage wall, you would fasten a ledger board, at the roof height and secure the roof joists to it and on the other side , 15' away, you would support the joists on a wall or posts and beam. Do I have the right idea?

Also, what is the snow load there?

Dave

My desire is to use roof joists only, 24" on center. You are correct in assuming I would fasten a ledger board to the wall studs and secure roof joists to it. The wall at the end, 15' away will be 2X6 and hold two patio doors.

My thought is to use just the floor joists. I am about ten miles from Belfast, Maine on the coast, and I don't really know what the snow load is here, but I think we have to plan for the potential of a pretty good load.

I believe you are in Canada so my snow load won't be a whole lot less than yours.

Roger

Hi Roger,

I looked up the snow load for Belfast, it is 60 psf, about twice the amount as us. I live on the West Coast of Canada, on Vancouver Island, British Columbia. Our precipitation is about half that of Vancouver, about 30 miles away.

Anyway, based on a snow load of 60 lbs per square foot, for a 15' span, your roof joist could be 2x10 spruce, pine, fir, #2 and better at 16" centers. For 24" centers, you need 2x12s, for sure.

Hope this helps,

Dave

Hello, Dave: Thanks very much. This does help a lot.

When I built my former home on the coast further east, we had a cathedral ceiling in the living room. I installed all the insulation in that house but had two professionals handle the framing. The cathedral ceiling was about twelve feet long and the pitch was 8/12 as I recall. Those roof joists were 2X12 I am quite certain. I wish to use 24 inch centers because it vastly simplifies the roof window installation.

Thanks so much for the assistance. You have a terrific website. I have been a developer for twenty years in one of my last careers, but the real carpentry was always done by pros. Now in my retirement I get to use what I have learned by observation, trial and error, seventh grade shop skills, sheer determination and now, your fine website with its fountain of information.

Tomorrow I use your instructions to cut my very first stair stringers. It should be interesting.

Roger

Thanks, Roger.

When cutting the stringer, remember to cut off the bottom of the stringer by the thickness of the treads. Most guys will do this, but they forget to drop the top step of the stringer down the thickness of the tread, as well. Otherwise the treads of the stringer won't be level. When the treads are installed the risers are all the same.

Dave

Dave,

I hope you can help. I want to add a Lean-To roof to my shed. I'm not sure how to frame to the shed roof. Also, should I remove the sheathing so framing directly to the trusses is possible? Would rather not. I would rather frame on top of the roof shingles and flash the seam. If possible, could you generate a quick drawing of the framing? I work best with pictures..;)

Sincerely,

Ern

Hi Ern,

There could be 3 ways to attach a lean-to roof to a shed.

- If the shed is high enough, attach it to the wall with a ledger and roof joists attached to the ledger and a post and beam or wall on the other side.

- If the shed is high enough and the soffits aren't framed in you could lap the existing rafters and extend them to form a lean-to roof.

- If the shed is not high enough, attach the lean-to roof to the existing roof, which sounds like this is what you want to do. The advantage of doing this is you can go up the existing roof, as far as the ridge to get the required height, which gives you the needed slope on the lean-to and the proper head room.

You don't need to remove shingles, but it does a better job of getting the lean-to framing down on the existing roof deck. Obviously, it depends on what condition the shingles are in and if they are laying nice and flat, etc. You may not need flashing between the old and new roofs, just continue the shingles over the lap of the lean-to.

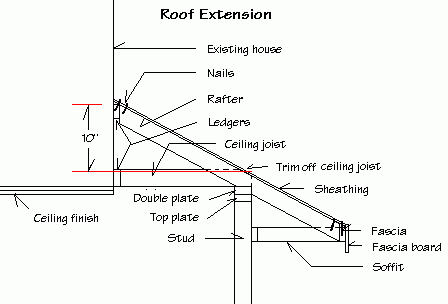

Here is a drawing of the 2nd and 3rd possibilities:

Here is a drawing for a roof supported by a ledger, as in #1:

This drawing shows rafters and ceiling joist. You could eliminate the ceiling joist for roof joists. I mainly wanted to show you the ledger idea. I have plans for a Patio Cover which details this idea: http://daveosborne.com/dave/projects/patio-roof.php

Also a lean-to roof plan: http://daveosborne.com/dave/projects/lean-to-shed-plan-6.php

I hope this helps,

Dave

Hi Dave,

First let me thank you for posting so many common jobs in layman terms that we all can understand. Not only do they empower us to do these ourselves but, if we have to hire out, we can use pro terms and procedures so they won't think we are ignorant to the whole thing.

I have a raised wooden deck (about 42" high) and I want to turn it into a sunroom. The building inspector okayed building the 12x12 structure on the existing deck. However, I did not realize that I do not know how to attach the ledger to the house. I am saying I don't know what the lag bolts would screw into. Is there typically a ledger type board under the gutters that I can tie into? Or, do I need to remove the vinyl siding, and house wrap to see what is under there? Thanks again for all you do.

Vic

Hi Vic and thanks for the nice comments.

Here is a link to our Patio Roof plan: http://daveosborne.com/dave/projects/patio-roof.php

The ledger is a board the same size as required for your roof joists that you fasten to the wall, tight to the sheeting. The ledger is attached to framing behind the wall, either vertical members, studs at either 16" or 24" on center. The box or rim joist is part of a floor frame. If you are above the floor level, there won't be a box joist to fasten to, just the studs. You can find these "hidden" studs with a stud finder or remove the vinyl siding and tear back the tarpaper or tyvek to expose the sheeting. You should do this anyway to fasten the ledger directly against the sheeting, into the studs. If there is a window on that wall you could fasten the ledger, above the window, to the window header. Here is a drawing of a wall without the sheeting, so you can see what is there:

Notice that the stud layout is independent of where the window is placed in the wall. We know that at the sides of the windows are a double stud, but you can't measure from these studs 16" to find the next stud. We usually frame all the headers the same - 2x10 tight to the underside of the top plate. This may not be the case in your house. We are only required to put a header in which will support the span, for example a double 2x4 header will support a 3 foot opening, you don't need a 2x10. The rest of the space is filled with upper window studs, just like below the window. Usually, for a house that is built within the past 20 years or so it will have solid 2x10 headers, unless the framers were "old school". You can see this quite clearly by removing the house wrap and seeing where the nails for the sheeting are. Tapping the sheeting will also tell you what is solid and what is not. Dave

Dave,

I'm building a soffit around some plumbing along the ceiling, it'll be appx 13ft long x 10" high. I'm planning on building it with some 1x2 to save space, need to get the sheet rock as close to some pipes as possible. What screws are the best for the smaller wood, to prevent splitting and so on.

Thanks,

Greg

Hi Greg,

Use the standard drywall screw that is #6 x 1 1/4". Go with a 2x2 where possible, especially on the outside corner. This makes it easier to screw from both sides of the corner.

Dave

Feature Article of the Month

(taken from our website: DaveOsborne.com

Remodeling 21: Wood Framing Answers

Question

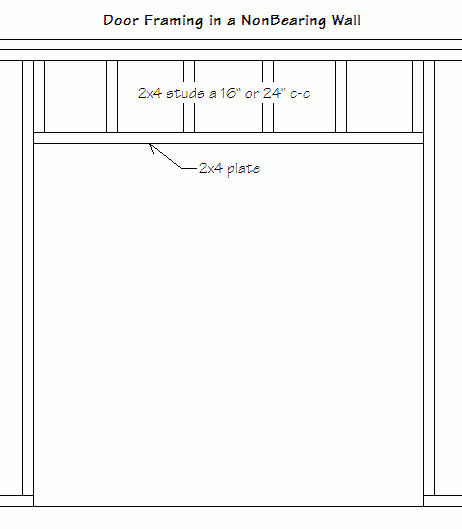

Could you please tell me how you build headers for closet bifold doors that are 6'0" wide on non-bearing walls? Do you just build them out of 2x4's?

Answer

A non-bearing wall doesn't need a header, as such. You only need a single horizontal plate with studs up to the top plate. Here is a drawing to clarify:

![]()

Remember that the opening for your bifold door is 6'-0" x 6'-8" finished, that is including drywall.

Dave

Question

Do you know how I might find information on building the walls and roof of a residential home from cement as they do in commercial construction? This seems like it would be an extremely strong and inexpensive building.

Answer

Concrete is not really inexpensive. The forming material alone would be the cost of the conventional framing. The roof slabs would require beams and posts to hold them up for 28 days. An engineer would have to be involved since it is not conventional. Forming pockets for plumbing and wiring through the walls and roof would have to be considered. Attachments for windows and doors would have to be allowed. Once built, it would last forever, though.

Most of the industrial buildings that I worked on were structural steel buildings with suspended slabs of concrete for the floors, the roofs were mostly steel as well. The buildings that were made totally of concrete were built that way for the structural strength required to support primary crushers and the like.

Commercial buildings including schools were built of concrete block with steel or timber roofs. I worked on high rise buildings that were mainly concrete construction. These are very expensive structures to build.

All things considered, I wouldn't advise building a residence out of concrete, there are too many better products out there. Concrete is best left to the footings and foundation walls.

... Read more at http://daveosborne.com/dave/articles/remodeling-wood-framing.phpAlmost the End

Well, that does it for another month. Thanks for your questions, hope my answers were helpful.

Dan and I appreciate your emails and support.

If you need more advice, please become a member of our website, then send me an email.

Your source for building tips, woodworking & furniture plans, house plans and building advice directly from Dave...

Hi, I'm Dave Osborne. With over 50 years experience as a journeyman carpenter, foreman and contractor in heavy construction I enjoyed working with apprentices and sharing the tricks of the trade that others shared with me. Now I get emails from Members all over the world and we include many of my answers in our Free Monthly Newsletters. Some of my answers include drawings and instructions specific to a project, but may also answer your questions. I use correct construction terminology, so you can confidently inform your building supply dealers or contractors exactly what you need.

ASK DAVE!

The Benefits of Membership

Membership gives you full access to our hundreds of how-to articles, woodworking plans, converters, calculators and tables. Our Stair Calculator is one of the most popular on the internet. We have projects you can build for (and with) your kids, furniture for your wife, and sheds and gazebos. If you run into a problem or need advice your Membership includes unlimited email questions to me through our Ask Dave quick response button.

Join us!

Copyright © 1999-2026 DDFM Enterprises. All Rights Reserved. DDFM ENTERPRISES, DAVE'S SHOP TALK and the Dave Osborne logo are trademarks and service marks owned by DDFM Enterprises. All other trademarks on this site are the property of their respective owners. Site design by Design Strategies, Inc.