Building Confidence

| Volume 16 Issue 8 ISSN 1923-7162 |

Welcome to Dave's Shop Talk's Home Improvement Newsletter of questions from our members on their construction projects, a Tip of the Month and a home remodeling article, both from our website at http://daveosborne.com.

Tip of the Month

Both the sill plate and the bottom plate of a house frame should be either pressure treated wood or bedded down on top of a sill gasket or both.

And a Bonus Tip:

When siding a house of various levels, start at the lowest elevation of the house.

Ask Dave!

Since the questions this month from our members were limited to none, I included some questions and answers from a previous newsletter.

I would like to know if you know the steps you had to review before installing a cabinets like uneven floor, bow walls etc because I work in Remodeling old houses. Maybe you know a website where I can read the information. Thank you. Adhemar

Hi Adhemar,

I have a plan for a corner cabinet which gives instructions on scribing the base to fit the floor. You can check it out at: https://daveosborne.com/dave/projects/corner-cabinet.php

With a bowed wall, I usually place shims between the wall and the cabinet and screw into the stud through the shim. I also screw the cabinets together, near the front. Another tip when installing the upper cabinets is to make a support for them to rest on, on top of the base cabinets. This helps especially when you are doing the install by yourself.

Dave

Hi Dave, We are building a small "inlaw" apartment onto our house and

have asked the builder to use pocket doors on each side of the bathroom.

My father-in-law had them on his other home and liked them and the new

apartment is very limited for space. The builder is dead set against it.

He says they're expensive, and will probably give us trouble down the

road that will result in tearing a wall out to do repairs.

Any suggestions?

Dave

Hi Dave,

I have installed pocket doors, one in my own home and never have had any problems with them. The door can be removed by removing stops and releasing it from the rollers on the track. The frame is actually part of the wall with the track attached to it. I've never experienced any problems with any of my installations. The door itself is the same as any other door, the frame and hardware is the only added cost. They are not my preferred door, but with limited space they are ideal especially for a small bathroom or closet. We have ours in a walk-in closet off our ensuite. One thing to watch is not screwing in a hanger or shelf into the wall and have the screw penetrate into the door.

Your builder has the right and should explain the pros and cons of your choices, but should also remember that he is working for you and should try to satisfy you to the best of his ability. I don't agree with why he is dead set against installing pocket doors.

Dave

Hi Dave,

Thanks for the great info. I bought a log cabin in Idaho and since

it wasn't lived in for 20 years, it's taking some work to get it habitable.

I used your instructions to do quite a few things. I'm in my 60's, female

and haven't really done much wood working. I even made my stringers for

stairs and they're great! It was quite a challenge without a decent saw

or even workspace. Anyway, I finally have indoor plumbing with a hot

shower and that's a treat. Each visit sees great progress.

I found your instructions for the stud wall confusing until I realized

you build it on the floor, flat and not upright like it is at the end.

My daughter said "build a stud wall" so I went to your instr first and

spent a small amount of time to get the message.

When I built the stairs, I left a little space for the sheet rock, like

you suggested. Several people didn't like that and I defended your

reasoning and that made them madder (I don't know why). Anyway, since it

looks like I'm doing the sheet rock myself, I appreciate the tip. thanks.

Thanks for all the tips and I enjoyed your trip reviews.

Georgia

Hi Georgia,

Thanks for the nice email.

I find it interesting your friends' reaction to the space in the stringers for the drywall. In construction we work with a lot of different trades. Carpenters are required to layout many things for some of the trades, so we get to work closely together. Anything we can do to help the sub-trades will increase the profit of the general contractor and decrease the bottom line of the owner. You can imagine the extra work involved for the drywall applicator to notch each step going down the stairs instead of just slipping a sloped piece into a space. This is an example of your friends not really understanding the procedure. I'm glad you took my advice and left the space, you will appreciate the consideration doing the drywall yourself.

Thanks again for the email, I love to hear success stories like yours.

Dave

Dave - Could you please tell me how you build headers for closet

bi-fold doors that are 6'0" wide on non-bearing walls?

Do you just build them out of 2x4's? thank you! - Trish

Hi Trish,

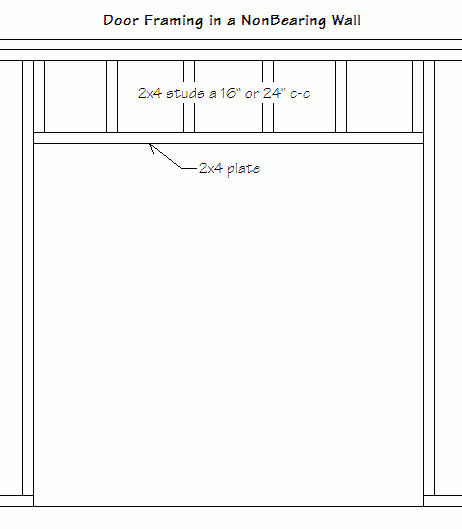

A non-bearing wall doesn't need a header, as such. You only need a single horizontal plate with studs up to the top plate. Here is a drawing to clarify:

Remember that the opening for your bi-fold is 6'-0" x 6'-8" finished, that is including drywall.

Hope this helps,

Dave

Feature Article of the Month

(taken from our website: DaveOsborne.com)

Cabinets 4: How to Make a Formica Counter Top

I know you can go into the large building supply stores and purchase a bathroom or kitchen cabinet formica counter top with a rolled top with little shaped end caps supplied as well. But, I would rather build my own kitchen cabinet formica counter top and include a bit of personality to it. I'll show you how.

On the left I've drawn six different profiles for the edges of your formica counter top, using a combination of formica and oak trim, for example.

On the left I've drawn six different profiles for the edges of your formica counter top, using a combination of formica and oak trim, for example.

Most formica counter top manufacturers today use K-3 particle board which, when exposed to water, from a kitchen sink area, will swell up and crumble away. I can't count the number of times I've seen this happen. Particularly around a kitchen or bathroom sink, I use plywood. Don't buy a sheet of G1S at $40 a piece, but 5/8" D-grade sanded or factory grade or even a select standard sheathing. Anything is better than particle board for around a kitchen sink.

In the corner of a manufactured rolled formica counter top is a miter joint right across the counter, just itching to get all wet and start swelling up or collecting dirt. Formica sheets come readily available in 4x8 and 5x12 sheets. In most cases, for the normal kitchen cabinet formica countertop, no joints are required at all, if you do it yourself.

The easiest way to make a formica counter top is to make it in your workshop with formica splash attached to cover the shape of the bathroom or kitchen cabinets. This helps in trimming off the formica with a router, being able to get around the counter top without a wall in the way.

Take careful measurements including how square or out of square the wall is, especially if the cabinet counter top is an L-shaped one. Make a template of two intersecting 1x4s with a brace between them if you have to. There will be a bit of adjustment for a wonky wall, but that's about all. If the wall is out quite a bit, this should be allowed for.

The basic formica counter top is made the same way for all the profiles shown in the drawings above. The edges will be different depending on the hardwood and the profile chosen. There are two options for the top, overhang the front of the kitchen cabinets or build up the top to have it come out flush with the top of the bathroom or kitchen cabinets. Flush is the standard today, unless making a top for a '60s set of cabinets. In the '60s, we used to make the counter top an integral part of the cabinets. That is, the top would help hold the kitchen cabinets together. We used to nail the plywood to the top of the cabinets and then apply the formica in place. We could never trim right to the wall with a router because the base plate would hit the wall, leaving about 3" of the edge not trimmed. We finished it by hand using a coarse file, block plane, or any other tool we could make use of.

For the formica top on the left, a piece of oak is attached to the plywood front to form an edge. Formica covers the plywood top and edge. The formica splash is made separately and attached by drilling holes through the plywood backing through the formica. The splash is then screwed into the plywood back, using silicone caulking to fill the voids. The formica is trimmed off by using a 45 degree bit with a ball bearing guide in a router, trimming the formica at the same time as it profiles the oak with a 45 degree bevel. Notice the oak cap on the formica splash. This adds a nice touch and eliminates the need to trim off the formica to the wall. This cap is installed after the splash top is in place and matches the oak on the edge. I keep the cap about 3/8" thick and overlap the formica splash about 1/8".

For the formica top on the left, a piece of oak is attached to the plywood front to form an edge. Formica covers the plywood top and edge. The formica splash is made separately and attached by drilling holes through the plywood backing through the formica. The splash is then screwed into the plywood back, using silicone caulking to fill the voids. The formica is trimmed off by using a 45 degree bit with a ball bearing guide in a router, trimming the formica at the same time as it profiles the oak with a 45 degree bevel. Notice the oak cap on the formica splash. This adds a nice touch and eliminates the need to trim off the formica to the wall. This cap is installed after the splash top is in place and matches the oak on the edge. I keep the cap about 3/8" thick and overlap the formica splash about 1/8".

In the drawing to the right (plan view), I've shown an L-shaped kitchen cabinet formica counter top with its backing attached to the bottom, usually 3" wide. The 5'x12' size indicates the maximum size of a sheet of formica without having to go with a joint. Remember when ordering your formica, to include material for the splash and edging as well.

In the drawing to the right (plan view), I've shown an L-shaped kitchen cabinet formica counter top with its backing attached to the bottom, usually 3" wide. The 5'x12' size indicates the maximum size of a sheet of formica without having to go with a joint. Remember when ordering your formica, to include material for the splash and edging as well.

The formica is applied to the plywood top with contact cement. Use a solvent based (not latex) contact cement in an area with lots of fresh air. The adhesive is spread with the use of a short pile roller that you discard when finished. The cement on the edging and splash can be applied with a disposable natural bristle paint brush. Apply the contact cement as instructed on the can by applying to both surfaces and leave until dry. When the two surfaces touch they will stick together and you won't be able to pull them apart. To compensate for this we either use a kraft paper or thin strips of wood or extra formica to place the glued formica in the exact position we want above the glued plywood. Since the glue is dry it won't stick to the paper or sticks, just to itself or other glued surfaces. When the formica is in position, pull the paper or sticks out carefully and the formica will stick to the glued plywood and can't be moved. When all the sticks are removed the formica can be rolled onto the plywood eliminating any air bubbles. If the formica covers the edge, instead of an oak trim, the formica on the edge is glued first. The top of the edge is trimmed off a tiny bit above the plywood to ensure a good seam. The plywood is then glued and formica applied with the top overlapping the edge. After the formica is rolled, the trimming procedure with the router can be done. Use a tapered formica trimmer bit with guide wheel and adjust the bit in or out by raising or lowering the bit in the router. Practice on a scrap piece first. Be very careful and slow in getting the bit to the exact position without cutting too much of the formica and having too wide a seam. I usually just trim off the formica to feel a slight burr, then sand the burr off with 120 grit sandpaper on a wooden block. Once you have gone too deep with the router bit, you have spoiled the piece, so take it easy and slow.

If you need a joint in the formica counter top pick a place that is the least noticeable. I choose the center of the sink for one spot. With using the plywood for a base, I have found through experience that there is no problem joining the sheets of formica at the sink. This way there is only about a 2" or 3" joint noticeable on each side of the sink, after it is installed.

There are products out there that can be used to fill in bad joints or repairs. These products are expensive, but they do the trick. They match the number on the formica sheet. This product is called FormFill Mitre Joint Sealant & Laminate Repairer, made in Australia. It has a match to the colors of the following brands: Wilsonart, Formica, Arborite, Nevamar, Pionite. They have a US distributor who's website is: http://www.formfillproducts.com and can be found at cabinet supply stores which usually cater to tradesman and kitchen cabinet shops.

Now that you know the basics, experiment a little and be innovative. Mix and match the formica with oak or other species of wood. I've even painted my wooden cap on the splash to compliment the color of the formica top. If you want to share your ideas with other members of this site, send me a picture of your creation and Dan will put them up on the member's photos page of the website.

Dan and I thank you for your interest and support of our Website.

Get complete access to our website - Subscribe Now!

We BUILD CONFIDENCE. If you need advice on Building or on your projects at work or home you can make a very small investment and subscribe to our website, then send me any questions or uncertainties you might have via email. There is no extra charge. That is all part of your membership to our site!

Please tell your friends and family about our site and this Newsletter.

Your source for building tips, woodworking & furniture plans, house plans and building advice directly from Dave...

Hi, I'm Dave Osborne. With over 50 years experience as a journeyman carpenter, foreman and contractor in heavy construction I enjoyed working with apprentices and sharing the tricks of the trade that others shared with me. Now I get emails from Members all over the world and we include many of my answers in our Free Monthly Newsletters. Some of my answers include drawings and instructions specific to a project, but may also answer your questions. I use correct construction terminology, so you can confidently inform your building supply dealers or contractors exactly what you need.

ASK DAVE!

The Benefits of Membership

Membership gives you full access to our hundreds of how-to articles, woodworking plans, converters, calculators and tables. Our Stair Calculator is one of the most popular on the internet. We have projects you can build for (and with) your kids, furniture for your wife, and sheds and gazebos. If you run into a problem or need advice your Membership includes unlimited email questions to me through our Ask Dave quick response button.

Join us!

Copyright © 1999-2026 DDFM Enterprises. All Rights Reserved. DDFM ENTERPRISES, DAVE'S SHOP TALK and the Dave Osborne logo are trademarks and service marks owned by DDFM Enterprises. All other trademarks on this site are the property of their respective owners. Site design by Design Strategies, Inc.