Building Confidence

| Volume 18 Issue 2 ISSN 1923-7162 |

Welcome to Dave's Shop Talk's Home Improvement Newsletter of questions from our members on their construction projects, a Tip of the Month and a home remodeling article, both from our website at https://daveosborne.com.

Tip of the Month

Usually a raised backyard wood deck has a slight drain, unless covered with a roof. Figure about 1/4" per foot, so that is a 3" drop in a 12 feet run.

For heights over 2 feet above the ground, we must install a deck railing or guard as the building codes call them. A deck railing should be at least 36" high, although 42" is more of the acceptable standard for high decks. The deck railing should be vertical barriers, rather than horizontal, where a child cannot climb up on them. They should also be less than 4" apart so that a toddler's head could not fit through and get stuck.

Ask Dave!

Dave, we are replacing a utility room countertop with a new quartz on. My question is whether it is necessary or not to remove the sink and existing countertop before they come to make a template for the new one. Many thanks, Jay

Hi Jay,

I suspect you should remove the existing sink and counter top, since they will need to scribe the wall. You may need an under top sink, as well, to work with the new top. Maybe ask the sink suppliers, just to be sure.

Dave

Hi Dave, I just used your stair calculator and it is fantastic! So, my "Detail of Placement of Stringer to Upper Floor" measurement is 8 9/32 from the top. This leaves 3 19/32 of stringer contact with the upper floor framing, in this case a multi layer 2x12 beam. What would you suggest for attachment of the stringer to the beam? 3 19/32 of contact for stairs seems kind of weak to me. Your brother deserves a compliment for the website and tools. I am a retired software engineer having worked on enterprise level software, your "stuff" is better than most corporations on-line today. Nice work! Kevin

Thanks for the question and nice comment!

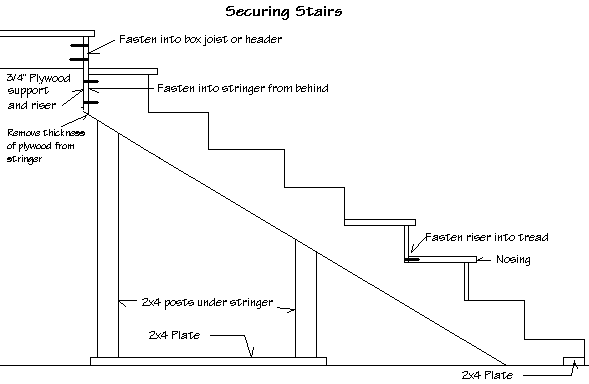

In a case like this I toe=nail the stringer to the header, just to hold it in place. I then put a post under the stringer near the top and middle for added support. If you want this stringer to be open underneath rather than supported by posts or a wall, I attach a 3/4" plywood to the two stringers as a riser. Cut back the top riser by 3/4" so you won't change the tread width of the top step. Here is a drawing to explain better, showing both methods:

Hope this helps, Dave

Thanks Dave this is a big help.

One suggestion for the stair calculator would be to add an option to have the top tread flush with the Upper Floor. This might be a "philosophical" issue, but I have found for stairwells accessed directly by a door (topside) that having the top tread flush with the floor was more safe when crossing through the doorway than having to make that first step. (My 2 cents)

Thanks again,

Kevin

Hi Kevin,

I'll talk to Dan about that top step even with the floor. I've had a few requests for help on that issue. I just figure out the rise and add it to the total run, then plug in that figure to get a new drawing which I alter to make it flush on top. Sometimes it's better to actually do the stair calculations manually. I do this for minimum run problems, as well. I believe the most important service to our members is to be code compliant. A door swinging over a step is not code compliant. I encourage our clients to ask questions! To every problem there is a solution, no matter how drastic.

Dave

Dave's Note: Dan and I agree with Kevin, that our clients should be able to decide for themselves which option they prefer for their stairs. I'm happy to announce that Dan has completed his revision to our Stair Calculator to give the option of laying out the stringer's top step to be flush with the top floor. Thanks, Dan, good job, as usual!

Dave

Dave,

I've been given the task to install artificial turf in the pool area around our neighborhood pool. Do you have any recommendations as to the type of turf, installation, etc?

Thanks,

Clint

Hi Clint,

This is a video from Home Depot which seems to cover the preparation and installation. I've never been involved in turf!

https://www.youtube.com/watch?time_continue=2&v=aDHEgZ1bG_E&feature=emb_logo

Hope this helps,

Dave

Feature Article of the Month

(taken from our website: DaveOsborne.com)

Deck 5: Deck Stairs with Returns

The construction of the deck stairs as shown in the above Floor Plan is a very complicated build, which incorporates the fundamentals of stair building combined with that of roof construction. If this is your first time in making stairs, refer to the How to Build Stairs articles on the web site. Also, details are given in How to Build a House 2: The Foundation.

I will compare the support of the miter of the steps with a hip rafter in a roof and the supports for the steps between the handrails with common rafters. Notice that the steps are 7' in both directions to produce a 45 degree angle with the deck line.

The height of the deck off the ground is 67", in our example; you can vary yours accordingly. The main thing I would like to accomplish here is to clarify the principle of building steps with mitered returns so you can apply your own measurements to suit your individual needs. I'll use this example of a set of return deck stairs throughout this article, but the chance of your actual project being the same is very unlikely, so I'll explain how the measurements are arrived at as we go.

The Foundation

You can see the perimeter measurements are 20'-4" x 7'-0"; your footing will be inside of that. The top of the deck is the reference for these elevations, so measure 68 1/2" down to the top of the concrete, which is the total rise plus 1 1/2" for the thickness of the 2x8. Concrete should be a minimum of 18" below the soil, depending on the frost depth in your area. The concrete should be 12" wide with a pressure treated 2x8 bolted to the top of it, flush with the outside edge of the footing. The stringer bottoms and supports will be nailed into this 2x8 sill plate. When the concrete is smoothed off on the top, insert 1/2" x 6" anchor bolts, leaving the threads up about 2" to bolt the 2x8 down. Place them no more than 6' apart. The footings in the middle are to support posts for the stringers, the two pads are for posts under the short stringers. Don't just rely on nails holding up the stringers; they should all be supported with posts—2x4 posts are good. Any wood laid down onto concrete should be protected with a 30 pound roofing felt or sill gasket under it or the wood pressure treated.

The Stringers

Under the mitered steps will be a stringer on a 45 degree. The other stringers will come off of this main one similar to jack rafters coming off a hip roof.

The rise and run ratio is 7.44/10.5 or 7 7/16"/10 1/2" on the common stringers. For the 45 degree stringers the ratio is 7.44/14.85 or 7 7/16"/14 7/8". Lay these out as shown in the article Stairs 2: How to Cut a Stair Stringer.

Here is a detail of the 45 stringer:

Notice the 45 stringer starts at the inside corner of the common stringers and has its end cut off on a 45 degree angle, similar to the plumb cut on a hip rafter.

Lay this stringer out with 8 rises of 7.44" and 8 runs of 14.85". After laying it out and cutting it out, remember to cut it off the bottom the thickness of the tread. Measure back from the first riser 11.98" and cut off the end plumb and on a 45. This is a compound angle of 45 and square with the top. You need two stringers like this, so copy one from the other. It's important to be very accurate with this.

Now cut the 7 common stringers; 3 will go in between the ones against the 45 stringers and 2 will be shortened by 1 1/2" at the top end to go up against the common stringers, against the 45 stringer. These are parallel to the deck as shown on the Stringer Layout drawing. These are laid out as normal, 8 rises at 7.44 and 8 runs at 10.5". Cut the bottom off by the tread thickness, 1 1/2" if you're using standard 2x6's for treads. (See How to Cut a Stair Stringer for more info on this.) Lay one out and use it as a pattern to copy the others. You need to make 12 jack stringers, so use the pattern for these, as well. Notice the plan for their different lengths, just subtract the number of runs at 10.5 each to make up the set.

Here is a detail of the Jack Stringers:

Notice how these stringers need to be extended by 1 1/2", then cut off on a 45 degree to fit the 45 degree angle of the 45 stringer. The rest of the stringer is the same as the common stringers. You need 4 sets of 3 with 2 of the sets cut off on the opposite 45 degree (mirror-image to the other 2 sets). The bottoms of these stringers are all alike since they all rest on the concrete pad, just cut them to different lengths.

When ready to assemble start with the common stringers and nail them into the deck starting at the inside edge of the 6'-4" measurement and nail into the 2x8 sill on the concrete. They come down from the deck surface 1 riser of 7.44 plus 1 1/2" tread or 8.94".

Before installing the treads and risers, place posts under the stringers next to the deck and in the middle of the span. This applies to all the stringers including the jack stringer, although a center post is not necessary for the two shorter ones.

The red lines next to this text show the backs of the riser, the same as the 10 1/2" run. Put the risers on first, then the treads over them to allow for a bit of overhang. The treads are mitered on the center of the 45 stringer, as are the risers. Two 2x6's will work well for each tread.

The treads should be 1 1/2" thick material for the spacing of the stringers. The stringers should all be made from pressure treated 2x10, except for the two 45 stringers which should be 2x12 pressure treated.

Read hundreds of diy articles, answered questions and dozens of plans and projects all written by Dave.

Become a Member and Dave will personally eliminate any doubts you might have about your projects by email.

Dan and I thank you for your interest and support of our Website. We hope we can help you with your present and future projects.

Get complete access to our website - Subscribe Now!

We BUILD CONFIDENCE. If you need advice on Building or on your projects at work or home you can make a very small investment and subscribe to our website, then send me any questions or uncertainties you might have via email. There is no extra charge. That is all part of your membership to our site!

Help us with the cost of putting this info out by becoming a member. Subscribe now!

Please tell your friends and family about our site and this Newsletter.

Your source for building tips, woodworking & furniture plans, house plans and building advice directly from Dave...

Hi, I'm Dave Osborne. With over 50 years experience as a journeyman carpenter, foreman and contractor in heavy construction I enjoyed working with apprentices and sharing the tricks of the trade that others shared with me. Now I get emails from Members all over the world and we include many of my answers in our Free Monthly Newsletters. Some of my answers include drawings and instructions specific to a project, but may also answer your questions. I use correct construction terminology, so you can confidently inform your building supply dealers or contractors exactly what you need.

ASK DAVE!

The Benefits of Membership

Membership gives you full access to our hundreds of how-to articles, woodworking plans, converters, calculators and tables. Our Stair Calculator is one of the most popular on the internet. We have projects you can build for (and with) your kids, furniture for your wife, and sheds and gazebos. If you run into a problem or need advice your Membership includes unlimited email questions to me through our Ask Dave quick response button.

Join us!

Copyright © 1999-2026 DDFM Enterprises. All Rights Reserved. DDFM ENTERPRISES, DAVE'S SHOP TALK and the Dave Osborne logo are trademarks and service marks owned by DDFM Enterprises. All other trademarks on this site are the property of their respective owners. Site design by Design Strategies, Inc.