Building Confidence

| Volume 21 Issue 1 ISSN 1923-7162 |

Welcome to Dave's Shop Talk's Home Improvement Newsletter of questions from our members on their construction projects, a Tip of the Month and a home remodeling article, both from our website at https://daveosborne.com.

Tips of the Month

Use clear plastic peanut butter or mayonaise jars for storage of screws. Mark the size on the lid with a felt pen.

To convert millimeters to inches, multiply by .03937. To convert meters to feet, multiply by 3.281. To convert square meters to square feet, multiply by 10.76.

Safety Tip: Maintain your power tools with care. Keep your power tools sharp, clean and lubricated. Wear safety glasses and dust masks. Use the power tool only when you are fit to operate a power tool, while not impaired.

Ask Dave!

Does the long edge of the aluminum fascia go under or over the drip edge? The roofer didn't nail the drip edge to the roof before he shingled, so I am wondering how the drip edge, fascia, soffit J channel, and eaves trough are fastened. Thanks

Hi Andy,

When applying exterior trim, etc., just like shingling a roof, always start at the bottom. The gutter, or eaves trough, is below everything, so everything above the gutter overlaps it. The alum. fascia is installed first, since it goes behind the gutter, then the gutter, the drip edge, then the soffit J, against the installed alum fascia on the inside. Where we don't use a drip edge, we extend the shingles about 1 1/2" past the sheathing of the roof, so that the shingles will eventually bend down over the inside gutter edge.

Here is a drawing:

You need to get under any roofing nails, along the first few inches up from the eaves. Lift up the nails with a flat bar, carefully. A helper is handy to carefully bend back the first row of shingles, so you can remove the nails and then slip the drip edge under the shingles and roofing felt at the eaves.

Then nail the felt and bottom row of shingles back, nailing the drip edges, as well. Put the nails back in the same holes, if possible. Then fold the top row of shingles over again. There should not be any roofing nails on top of the shingles. There is a mastic strip that should stick the top shingles to the row below it, when the heat of the sun gets to it.

Dave

Dave, I am planning to install 5/16" x 3" x 8' pine paneling in the cabin. Can I install this right on the studs and trusses or do I need to put up drywall first? I am hoping not to put up drywall as this is a cabin, not our permanent home. Thanks

Hi Andy,

5/16 isn't very substantial for a wall or ceiling covering on its own, for 16" studs or 24" trusses, it needs backing. Strapping a wall is good with old 1x4 or whatever, it doesn't need to be solid like drywall. How about strapping the wall on 12" centers and install the pine on a 45 or vertically?

Dave

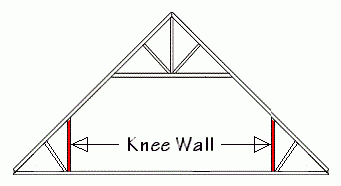

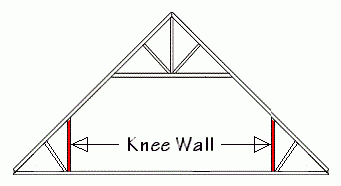

Hi Dave, the attic trusses in my cottage are 2x8 between the ceiling and the knee wall (see diagram), which doesn't allow a lot of room for insulation. I am insulating (all fiberglass) the cottage roof at R-56 which is 17" of insulation. What should I do about the section of the attic truss which is only 7 1/2"?

Also, do I need to use ventilation chutes when I am insulating? Thanks

Also, do I need to use ventilation chutes when I am insulating? Thanks

Also, do I need to use ventilation chutes when I am insulating? Thanks

Also, do I need to use ventilation chutes when I am insulating? Thanks

Hi Andy,

This is a very good question.

In a situation, like a vaulted ceiling, like this, you are required to strap the roof with 2x4s to allow for cross ventilation. This is something you should discuss with your building inspector. Of course, this needs to be done before the roof deck is applied.

Check out, in your area, if they have readily available a high density insulation for the 7 1/4" space. You may need to use Styrofoam at this location, whichever gives the higher R-value.

Another option is to drop the ceiling, a bit in this location. Whatever, I'm sure you would need to strap the roof, though. It is important to check this out with the inspector.

The ventilation chutes are used at the soffit to roof line to ensure the insulation doesn't plug up the ventilation from the soffits. They are used when you blow insulation in. Every other truss space is vented. You may be alright with the fibreglass, if you are careful to go just over the outside wall and leave space between the strapping and the top of the insulation, for ventilation from the eaves. With the strapping over the the entire roof, you should be okay.

Dave

Dave, as you might remember, I had a pole building put up this past fall. I am in the process of finishing off part of it for a workshop. I am using 2 X 6 framing. What I have noticed about a metal frame bldg; is the fact that is sweats a lot as the weather changes. My question: I have completed all the wiring and ready to do the insulation. I want to use fiberglass [R-18 or better] in the walls. Since the metals sweats; Should I put something between the bare metal skin and the insulation?? I also plan on using a "vapor barrier" before I put on the sheetrock. Just trying to "second guess" myself because I don't want to run into moisture problems later on. I will be putting heat in the shop as well as insulation and rock in the ceiling. Hope you and yours had a great holiday. Thanks for your help. Kelly

Hi Kelly,

Once you put the insulation in, the condensation should stop. To ensure keeping the insulation dry, I would apply only a wall type tarpaper (breathing) against the sheet metal, if not done with the initial installation. Don't put any poly on the cold side, which would cause more condensation.

Dave

Dave, I have another question. I have finished the framing and wiring; my next step is the insulation. There is nothing between my studs and the outside walls. Before I put in the insulation should I use something like styrofoam sheets [1 inch thick] against the bare wall, then my R-22 or R-28, then a "vapor barrier" and finally the sheetrock to finish the walls. Since this is my first experience with a metal framed building, I'm not sure how to proceed. In the past all my prior buildings have been the conventional "stick frame type". If I had unlimited funds, I would just get a contractor to come in and spray a coating of styrofoam for the insulation; but I don't have that kind of money. Thanks again for your help. Kelly

Hi Kelly,

It would have been better during the metal siding installation to apply 2 layers of tarpaper (when no sheathing is installed). Now that the siding is installed without the tarpaper, it still is a good idea to put it in from the inside. Just cut the rolls in half and bend them to fit between the studs and tight to the siding. Staple it in place against the studs. If there is 1x4 strapping on the outside studs, so the siding is fastened to the strapping, no need. The air space will eliminate any condensation. For the choice of tarpaper, use 30 minute or 60 minute and start at the top, so that if there is any overlap, it will lap so any outside moisture runs down the paper to the outside.

I wouldn't use 1" Styrofoam, since it is fairly expensive, as well.

Dave

Hi Dave. Came across your website yesterday and joined immediately. I am doing a total remodel of a home. My question for you involves framing of a fireplace surround. I removed the old brick surround. The wall where the fireplace is framed so I can apply insulation (old brick colonial no original exterior wall insulation). The fireplace is not framed. The goal is to create a stone veneer surround then insert a wood stove (chimney is lined). Question: does the framing around the surround need to be metal or can I use wood if the frame will be covered by cement board and the stone veneer? I am trying to meet code, which I know is governed locally.

Hi,

Wood framing around a fireplace or stove is okay with these restrictions:

- Framing lumber has 2" clearance against the wood stove

- finishing material of sheathing has 1" clearance

- zero clearance between the stove and non-combustibles such as the stone or ceramic tile, etc.

- back clearance is 4" clearance on an inside wall and 2" on an outside wall from the stove

- hearth should be 16" in front of the stove extending 8" beyond the stove opening on each side

- above the opening clearance is 12" to combustibles

- no combustible material within 3" of the face of the stove

The fire department governs the code in our area, as well as the inspections.

Dave

First; THANKS for the Calculator...works great! I'm building a set of stairs with a total rise of 110 7/8"...total run of 150". Fifteen steps of roughly 7" rise and 10" tread. The rough opening in the well is 45". I plan to use 1" ply for the treads. Do I need more than three stringers..one each side/one center?

Hi,

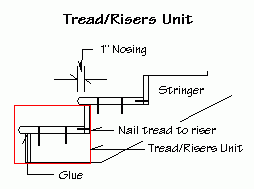

Using 1" ply really helps stabilize the tread, if you glue (using Construction Adhesive, in a tube) the tread to the stringers, the riser at the front and fasten and glue the riser at the back. So to be able to do this follow the following sequence:

- fasten the lower riser on first, with the top of the riser flush with the stringer at the front

- fasten the upper riser same as the bottom one

- fasten the tread to the stringers, apply glue to the top of the riser at the front

- fasten the bottom of the stringer, with glue, to the back of the tread

In this way, you don't need a middle or anymore stringers, since the span on the tread is not 45" but the 10" of the tread between the riser and the front and the riser at the back of the tread. No problem putting in a center stringer, for added security.

Here is a drawing:

Dave

Thanks for the reply. We did go ahead and cut additional stringers but I'm leaving it up to my son to decide how many to use re: codes in Hawaii. I do want to say though that I looked at a lot of resources, books, and many on-line offerings. Many seemed to cover a reasonable approach but I chose your method because it gave me EXACT distances and a visual plan that I could refer to as I measured and cut. The idea of laying out one stringer and then using it as a template (as suggested by others) never seemed a good idea. We choose four very nice 2xs for the stringers but each had some small crown etc. Even when I cut the crown edge I found that I would never have trusted the first stringers to act as a template for the others, due to bowing, etc. Being a jeweler by trade, the ability to cut out four boards using the exact measurements gave me sense of reliability along the length of the 14+ feet. The notion that such a 15 tread stringer could be laid out by stepping the square along the edge, with no guidelines (as others suggested) was scary. THANKS for the time it took to set up that Calculator. I'm confident that the stringers I cut will assemble the stair way well, regardless of how many stringers my son elects to use. I appreciate your time Steve

Hi Steve,

I liked your comments on the stair calculator, interesting points of view coming from a jeweler. My brother actually thought of that method. He is a mathematician rather than a construction guy. It is a very accurate way of laying out stairs. We used the step down method for years before they had calculators or computers. Personally, I would still copy the other stringers from the original pattern, rather than layout each one again and again.

Hope all goes well.

Dave

Feature Article of the Month

(taken from our website: DaveOsborne.com)

Stairs 2: How to Cut a Stair Stringer

A stair stringer is one of the boards that hold each stair in place. Stair stringers run the length of a straight staircase (see Figure 1).

Size of the Stair Stringer

In choosing the size of your stair stringer, a 2 x 10 should be the smallest board chosen. A rule to follow is: the amount of solid wood remaining on the stair stringer after the stair rise and stair runs are cut out should be a minimum of 3 1/2" to support the weight of your 350 pound neighbours when they come over to inspect your work. (See Figure 1.) In some cases, a vertical post or two can be placed beneath the stair stringer to the floor to help support the stairs. In other cases, the stair stringers can be nailed securely to the sides of the walls for added support. When circumstances demand no posts under the stair stringer or walls for support, use a 2 x 12 stair stringer for added protection.

The Stair Stringer Layout

Laying out the stair stringers is a very precise job. With 14 stair rises, a mistake of 1/16" can multiply to a mistake of 7/8". Get your framing square, stair gauges and a sharp pencil from your tool box and let's get to work. The framing square is made up of two legs joined at the heel to form a right angle. The longer leg, called the body is 2" x 24" and the shorter one, called the tongue is 1 1/2" x 16". If you hold the body of the framing square in your left hand with the tongue pointing to the right you are looking at the face of the framing square, which usually has the brand name on the heel. The back of the framing square is the reverse side. Along the edges of the body and tongue on both sides are the graduations of the framing square. These consist of the following fractions of an inch: eighths, tenths, twelfths, sixteenths and thirty-seconds.

Figure 2 shows the correct method of laying your framing square on the stair stringer. Start at the top end of the stair stringer near the end of the 2 x 10 or 2 x 12. With your stair gauges guiding the framing square in place at the 7 5/8" stair rise and 10 1/2" stair run positions where they meet the edge of the 2 x 10, scribe very sharp lines along the edges of the framing square, so the lines meet at the framing square's vertex. Slide the framing square along the stair stringer until the rise marker on the framing square meets the first run mark you drew on the board. Continue this procedure along the full length of the stair stringer board until you have counted the full number of stair rises and stair runs you calculated earlier, in our example these are 14 stair rises and 13 stair runs. One thing to watch with the framing square is to make sure you take your stair rise and stair run from both the inside or the outside of the framing square. Where your pencil marks meet must be where the framing square starts its measurement.

Figure 2 shows the correct method of laying your framing square on the stair stringer. Start at the top end of the stair stringer near the end of the 2 x 10 or 2 x 12. With your stair gauges guiding the framing square in place at the 7 5/8" stair rise and 10 1/2" stair run positions where they meet the edge of the 2 x 10, scribe very sharp lines along the edges of the framing square, so the lines meet at the framing square's vertex. Slide the framing square along the stair stringer until the rise marker on the framing square meets the first run mark you drew on the board. Continue this procedure along the full length of the stair stringer board until you have counted the full number of stair rises and stair runs you calculated earlier, in our example these are 14 stair rises and 13 stair runs. One thing to watch with the framing square is to make sure you take your stair rise and stair run from both the inside or the outside of the framing square. Where your pencil marks meet must be where the framing square starts its measurement.

I've mentioned before that there is one less stair run than stair rise. When laying out the stair stringer the extra stair rise is not on the stair stringer, but is measured down from the top floor or deck. This leaves the stair stringer itself with an equal number of stair rises and stair runs.

The Bottom Stair Riser

The stair stringer is laid out with the correct numbers of stair rises and stair runs. Now we must compensate for the bottom stair riser when we add the stair tread on top of it. The BC Building Code stipulates that the minimun thickness for a stair tread is 25 mm.(1"). Carpenter framers making stairs in a new house rip 1" plywood into strips for the stair treads or use 1 1/2" lumber. In our example let's use 1" plywood as our stair tread. Now take 1" off the bottom step of the stair stringer. The bottom of your finished stair stringer should look similar to Figure 3.

Installing the Stair Stringer

When installing the stair stringer to the stair opening, measure from the top floor down the face of the trim joist to the rise measurement, say 7 5/8" and then add on the thickness of stair tread or 1" that you took off the bottom of the stair stringer. If the stairs are going between 2 walls and the finish, probably drywall, is not on the walls yet, as is the case in new construction, before installing the stair stringers nail a 3" ripping of 5/8" or 3/4" plywood along the bottom outside of the stair stringers. This enables the drywallers to come after the stairs are in and slip the drywall between the wall and the end of the stairs, rather than having to cut out the drywall in the shape of each stair. They will appreciate your consideration. It will save you a few bucks, too. If the walls are finished, of course, just nail the stair stringers to the studs right through the finished walls.

Dave

Almost the End

Read hundreds of diy articles, answered questions and dozens of plans and projects all written by Dave.

Become a Member and Dave will personally eliminate any doubts you might have about your projects by email.

Dan and I thank you for your interest and support of our Website. We hope we can help you with your present and future projects.

Get complete access to our website - Subscribe Now!

We BUILD CONFIDENCE. If you need advice on Building or on your projects at work or home you can make a very small investment and subscribe to our website, then send me any questions or uncertainties you might have via email. There is no extra charge. That is all part of your membership to our site!

Help us with the cost of putting this info out by becoming a member. Subscribe now!

Please tell your friends and family about our site and this Newsletter.

Dan and I wish all our readers and members of our website, all the best in 2023 and stay safe out there and thanks to our Front Line Workers.

Your source for building tips, woodworking & furniture plans, house plans and building advice directly from Dave...

Hi, I'm Dave Osborne. With over 50 years experience as a journeyman carpenter, foreman and contractor in heavy construction I enjoyed working with apprentices and sharing the tricks of the trade that others shared with me. Now I get emails from Members all over the world and we include many of my answers in our Free Monthly Newsletters. Some of my answers include drawings and instructions specific to a project, but may also answer your questions. I use correct construction terminology, so you can confidently inform your building supply dealers or contractors exactly what you need.

ASK DAVE!

The Benefits of Membership

Membership gives you full access to our hundreds of how-to articles, woodworking plans, converters, calculators and tables. Our Stair Calculator is one of the most popular on the internet. We have projects you can build for (and with) your kids, furniture for your wife, and sheds and gazebos. If you run into a problem or need advice your Membership includes unlimited email questions to me through our Ask Dave quick response button.

Join us!

Copyright © 1999-2026 DDFM Enterprises. All Rights Reserved. DDFM ENTERPRISES, DAVE'S SHOP TALK and the Dave Osborne logo are trademarks and service marks owned by DDFM Enterprises. All other trademarks on this site are the property of their respective owners. Site design by Design Strategies, Inc.